AssetTracker Pro Example Workflows

Your Workflow, Your Data, Your Rules

Capture data in your business or organisation the way "you" want to. Increase productivity with standard workflows and improve data accuracy with standardised data capture.

Bulk Laundry Processing

Capture capacity and volume of laundry assets in your system to minimise costs

All user access to ATP is controlled by your organisation via your own private administration dashboard.

You can assign users to the mobile app individually or as groups.

When using shared group devices with one shared user login, individual user IDs can be captured using a barcode or RFID tag via a user ID badge and easily scanned into ATP.

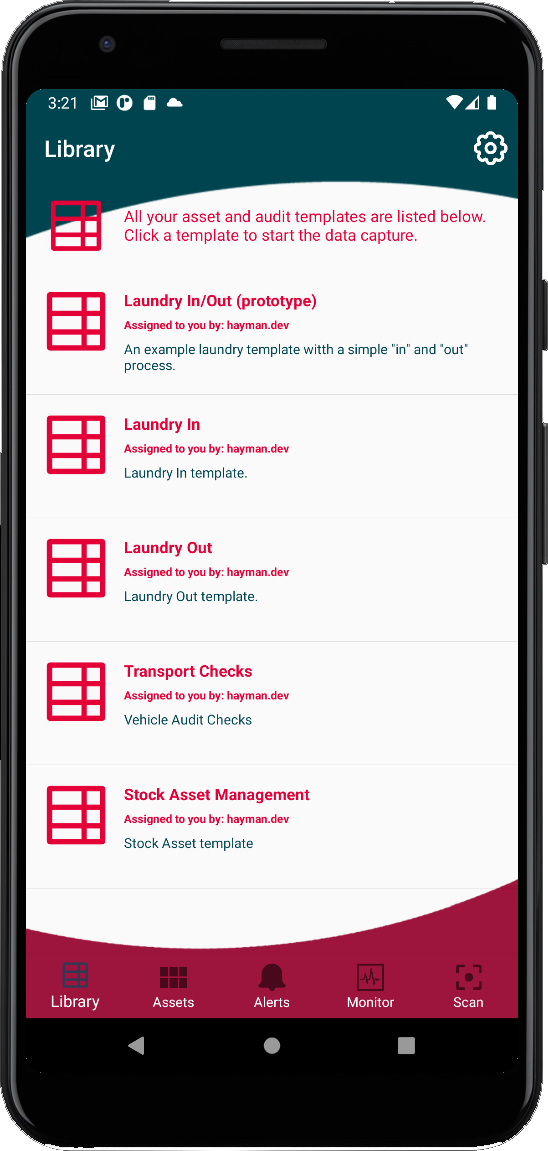

Once logged in, the user will be presented with one or more workflows.

Each workflow represents a different task or process flow your user needs to follow to complete a job.

Users can be assigned to different workflows to perform different tasks and processes.

Workflow tasks and process are created by our Workflow Builder software and customised to your requirements.

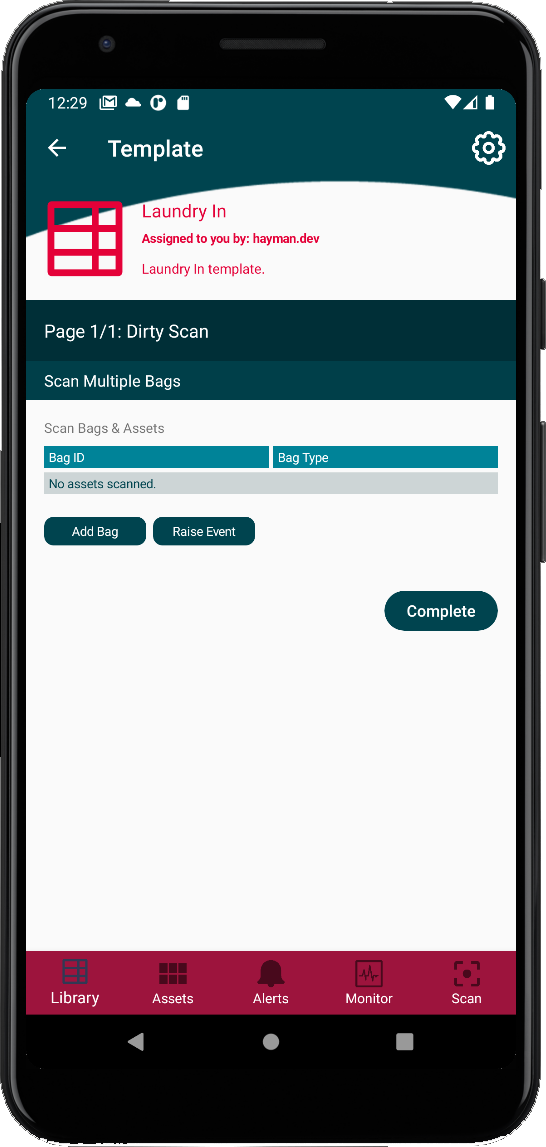

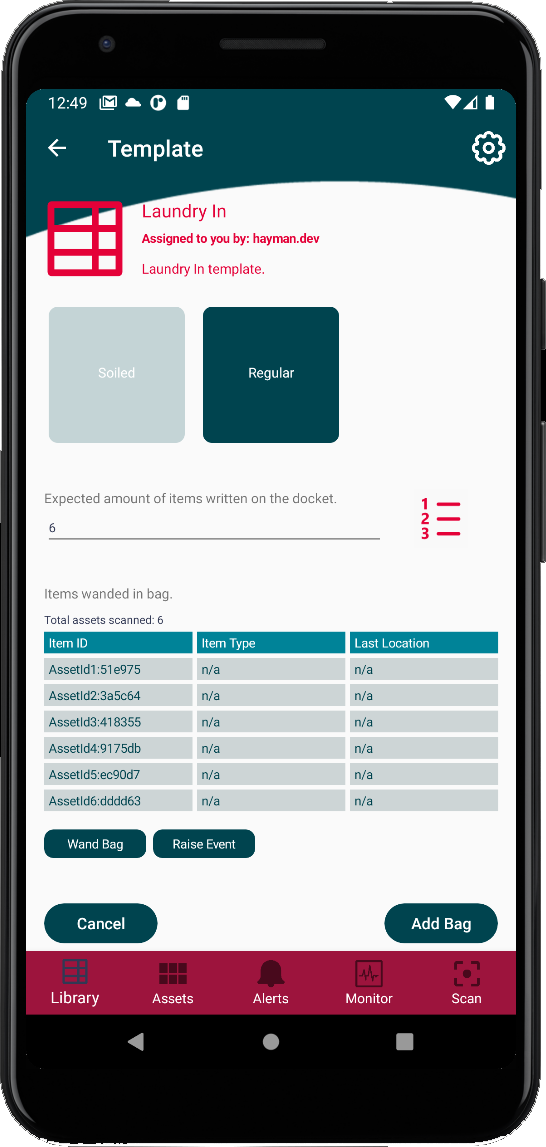

Before the first dirty laundry scan is made, ATP creates a new "session" with the user. A session is the time it takes a user to add assets to be processed. This table shows the current assets added, which in this example, is currently none.

Each asset that is scanned on the next page, is shown here in summary. The columns in the table can be customised to show the asset’s last scanned data and can be configured via the template properties to show different data.

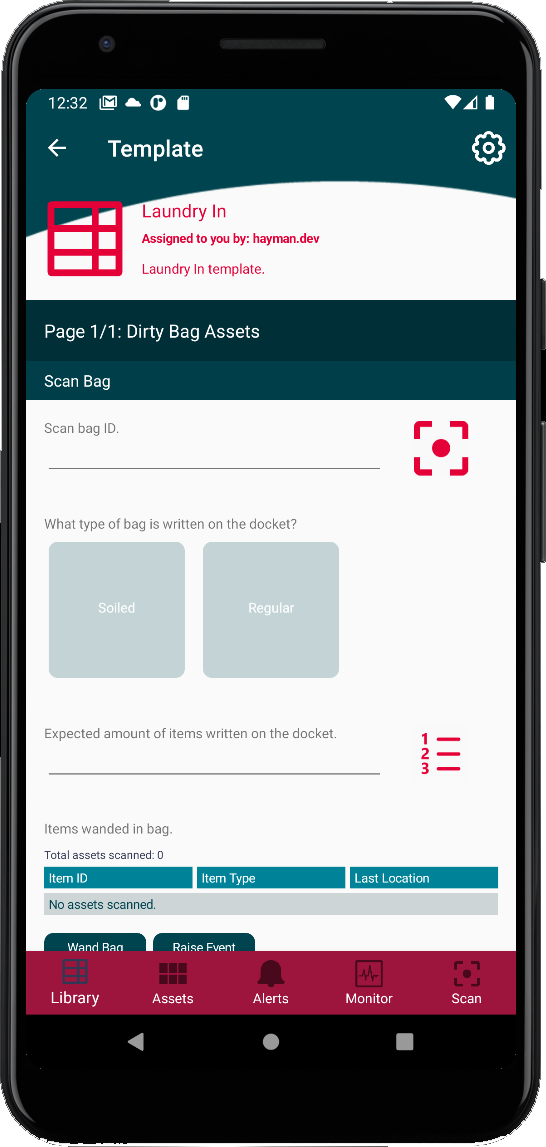

A user maybe presented with multiple dirty laundry bags to process. Some are marked as "soiled", others as "regular".

Regular laundry bags have their UDI barcodes scanned and their contents "wanded" to capture any RFID attached tags.

Soiled bags cannot be emptied by the user, so they are instead scanned and placed immediately on the conveyor belt to be automatically washed.

The asset UDI’s wanded by the user are shown in the table after capture. These appear in one or two waves of the wand.

The user empties the bag contents and performs a visual count of the assets to ensure the same amount that was wanded matches the physical amount emptied.

The assets and the laundry bag are loaded onto the conveyor belt which transfers the laundry through the washing cycle.

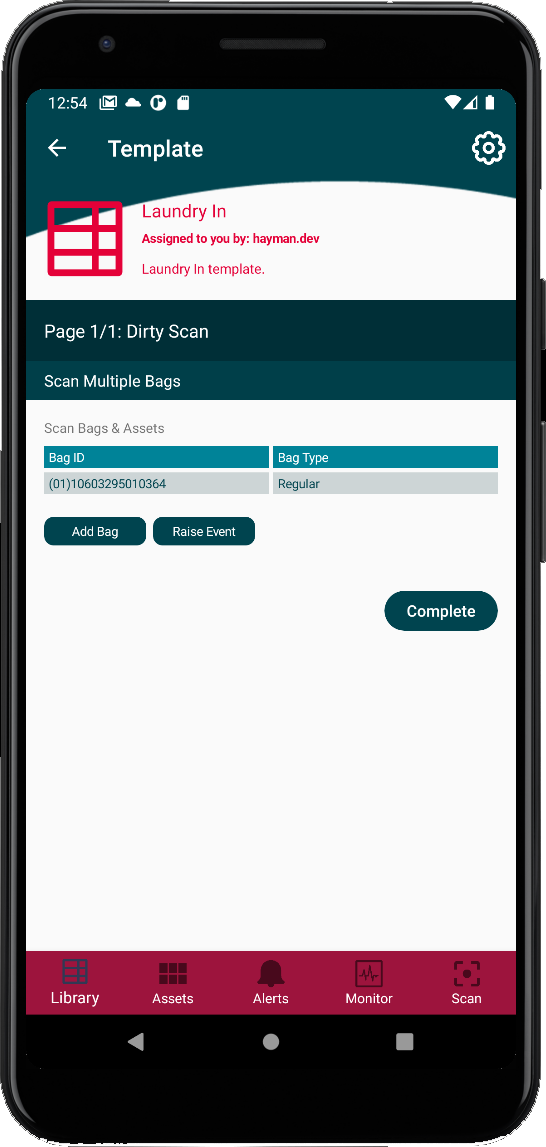

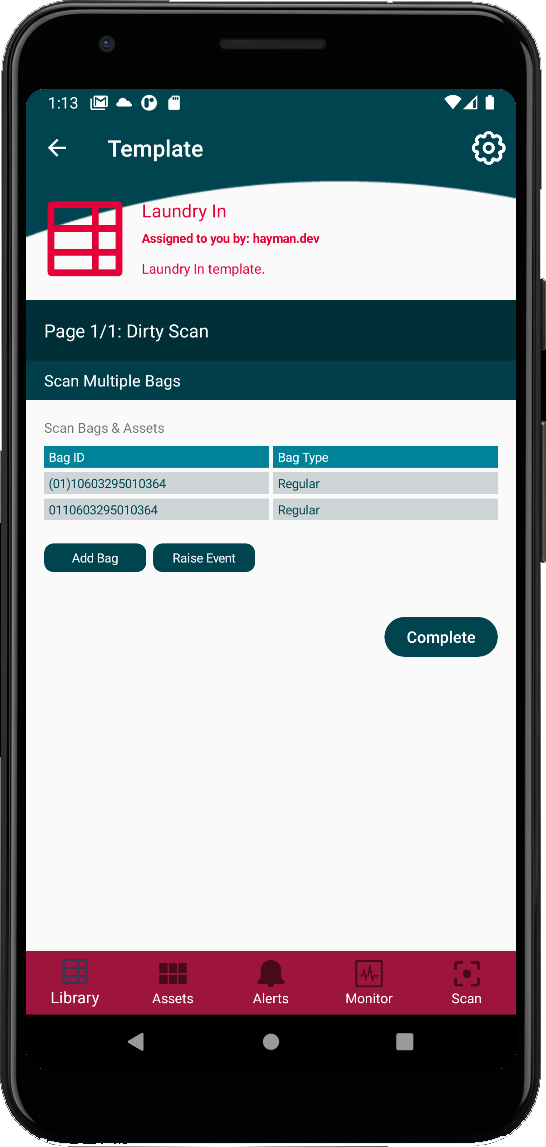

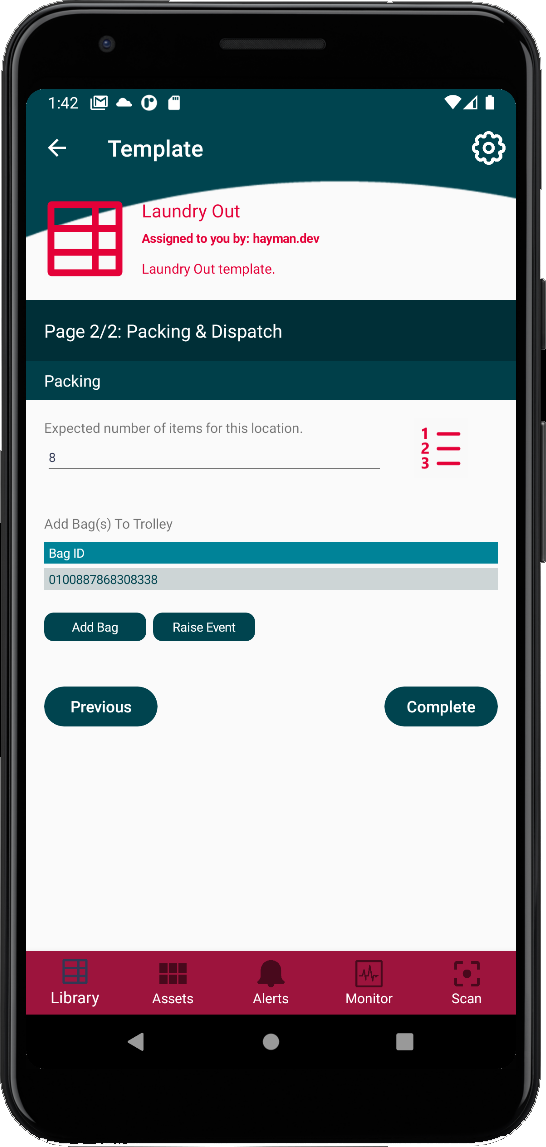

With the bag and its contents stored in ATP by tapping the "Add Bag" button, ATP returns the user to the initial session screen where it waits for the next laundry bag to be scanned.

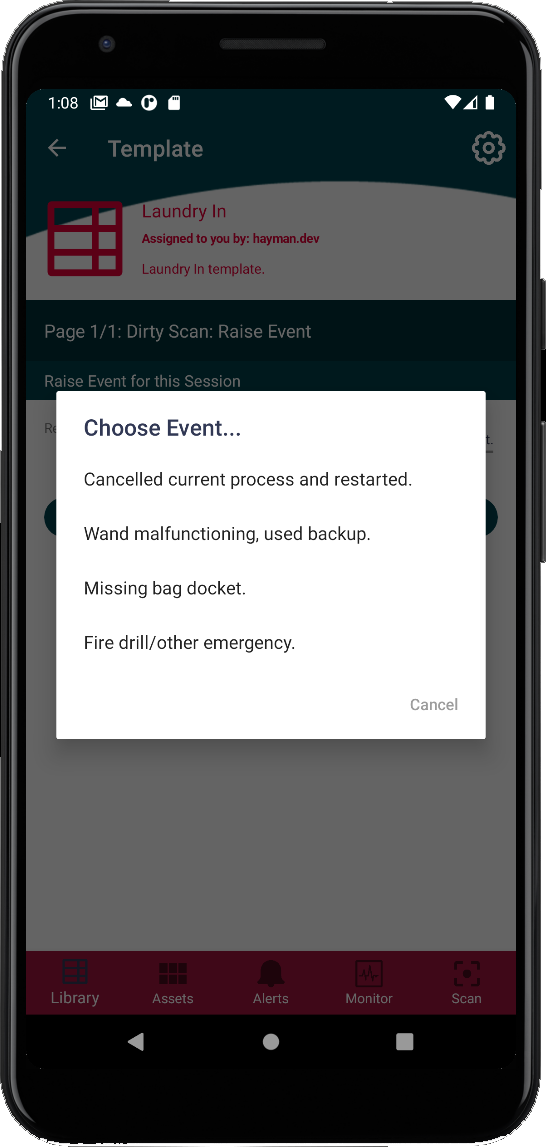

A user can raise an event from this screen or via the "Add Bag" screen to raise events which will appear in the reporting or notification system. These will warn managers of any issues encountered, such as missing RFID tags, damaged assets, or malfunctioning devices.

Raising events can be customised via the template properties allowing easy re-configuration of notices.

With no laundry bags left to process, the user’s session is now complete.

By tapping the "Complete" button, ATP re-verifies all the data and automatically syncs it to the ATP Server which can be located in the cloud or on-premises.

If no connection is available at the time of syncing, ATP holds the data on the device until a connection is remade to the ATP Server and syncs the data in the background.

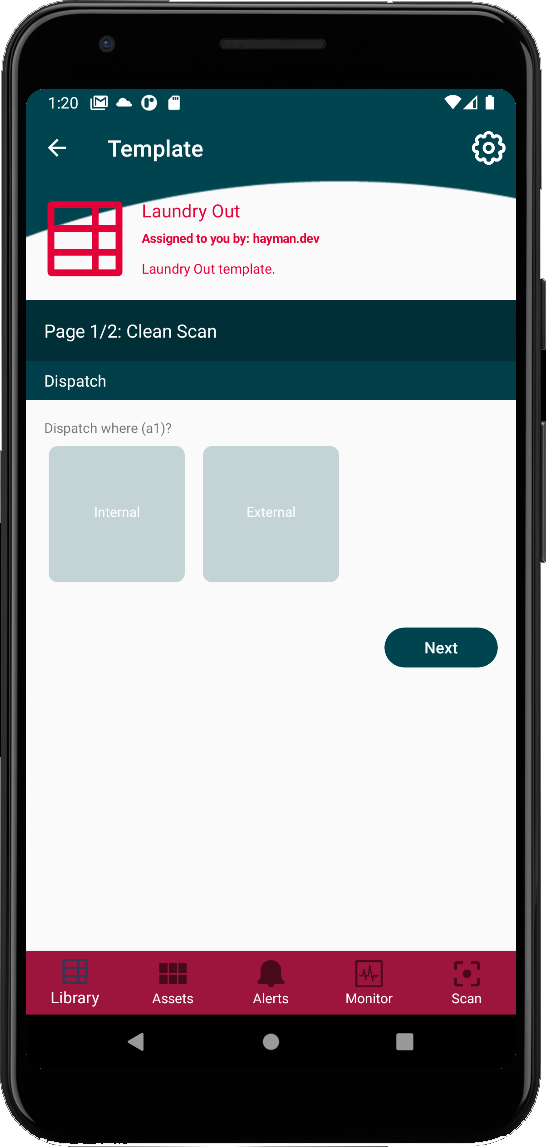

With clean laundry ready to be dispatched to wards and commercial locations, the user now has to make a few decisions to determine "what" needs to be sent "where" and at what quantity.

If at this stage a user notices an asset is still dirty, it is sent back via a "re-processing" template that records the asset UID.

This allows a re-processing cost to be calculated for assets via reporting.

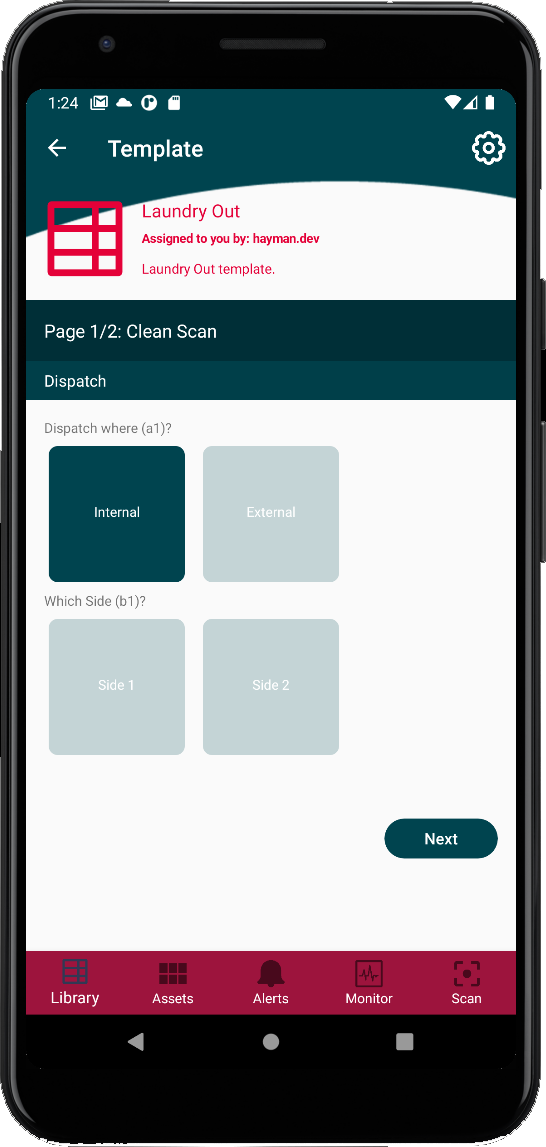

ATP has many different ways to present decisions to users, in this example we have set up a decision tree that offers the user different choices as they tap each option in turn.

This decision tree represents a final location where assets should be dispatched too, but there may be many options to choose beforehand.

A decision tree can be configured via the template properties and can consist of as many levels as you need.

Once the user has completed the choices available to them, the final option shows the locations where the clean laundry should be despatched.

ATP treats these locations as "assets", allowing you to use our reporting system to generate data based not only on the assets processed in laundry, but also the locations they are despatched too.

This is a very powerful feature allowing detailed analysis of data throughout the lifecycle of your assets.

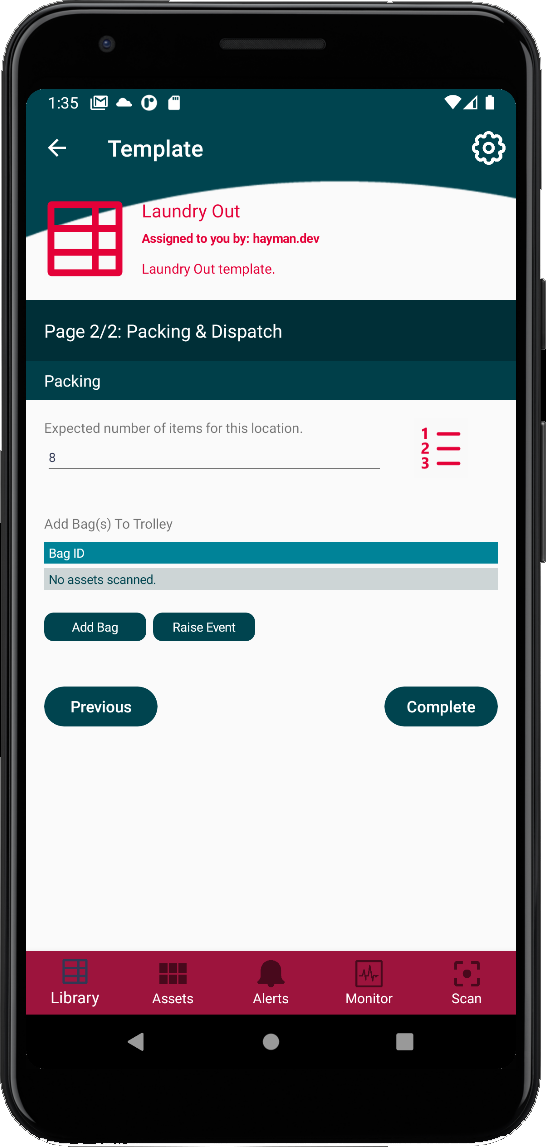

With a location selected, ATP shows the user exactly what assets are required to be despatched to this location.

As the location is an asset, and ATP allows properties to be assigned to assets, we can configure via the template, the quantity and type of assets required at the destination.

More than one laundry bag may need preparing, this starts a new session for the user to add single or multiple bags to the desired location.

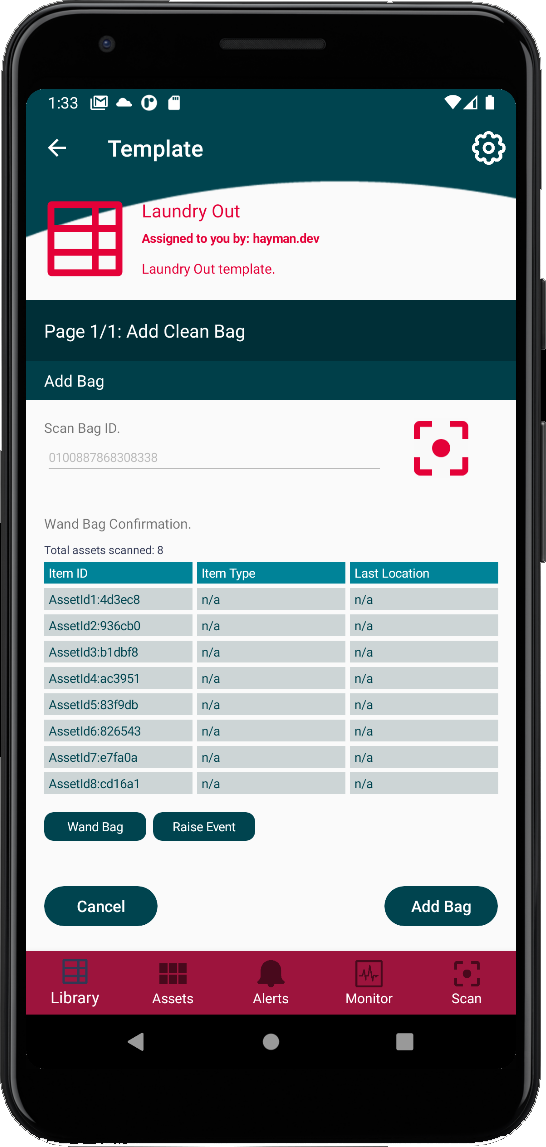

The user takes a clean empty laundry bag and scans its UDI.

With a list of assets to add to the bag, the user proceeds to add the items as required by the system.

Once the bag is filled, the user once again "wands" the bag to capture all the RFID tags attached to the assets. ATP now knows the despatch location, bag, and assets it has carried. Each location and bag are defined as "groups" for detailed reporting and analysis.

With the bag completed, the user has completed their session and the bag is ready to be loaded onto a trolley or cage for despatch.

To extend this process, an additional template could be created to capture the trolley/cage UID and the user transporting the assets to their despatch location. Further, by using fixed RFID scanners, ATP could also automatically scan the asset UDIs as they pass through the door at their final destination.

AssetTracker Pro Framework

Flexible, Scalable & Bespoke

Because not everybody's asset tracking, auditing or workflow management is the same, our framework offers the benefits of starting with standard modules and blending them to suit your needs.

Announcements & Awards.

Proud to announce we've been awarded access to the UK Governments G-Cloud 13 framework.

We're a Microsoft Partner and ISV, currently participating in the UK ISV Success Programme.

Effective, Government backed minimum standard scheme that protects against the most common cyber attacks

All organisations that have access to NHS patient data and systems must use the Data Security and Protection Toolkit.